Contents

- 1 What is the Meaning of Kitting in Manufacturing?

- 2 What are the Types of Kitting?

- 3 What are Some Examples of Kitting?

- 4 What are the Benefits of Kitting?

- 5 How to Implement Kitting?

- 6 What are Some Best Practices to Follow in Kitting?

- 7 Next Step: Empower your Kitting Strategy with the Right Tool

- 8 Summing up

- 9 Frequently asked questions

Imagine a customer places an order for five related items. Each of them is stored in a different part of the warehouse. Without kitting, fulfilling customer orders becomes a time-consuming scavenger hunt. With kitting, it’s a single, pre-assembled package ready to ship.

What is the Meaning of Kitting in Manufacturing?

Kitting is a manufacturing strategy where related but different products are grouped, packaged, and shipped together as a single unit, or a “kit.” These kits are often pre-assembled based on customer needs or recurring order patterns to streamline order processing.

Did the meaning of kitting ring a bell? Bundling, assembly, and kitting are distinct terms with some similarities.

- Bundling usually focuses on selling complementary products together (often at a discount); for example, selling a cleanser with a moisturizer at a discount. Unlike a kit, a bundle is sold as two separate products with different stock keeping units (SKUs).

- Assembly refers to the physical creation of a new product by combining its constituents; for instance, creating a customized eyeshadow palette where individual shades are physically inserted into a single compact before shipping.

- Kitting, on the other hand, is all about packaging items so they function as one product during delivery; for example, selling a “Morning Skincare Kit” with cleanser, serum, and moisturizer, packed together and shipped as one unit. A kit has a single SKU.

What are the Types of Kitting?

Kitting comes in different forms depending on where and how it is applied in the supply chain. Each type serves a unique purpose, from speeding up fulfillment to offering ready-to-sell product kits. Here are its main types:

Warehouse Kitting (Product or Inventory Kitting)

This is the most common type and customary for a wholesaler’s order fulfillment process. When a customer places an order for a kit, the wholesaler’s warehouse staff pick each item in the kit. They then assemble the kit at a dedicated kitting or packing station before shipping to the retailer.

Manufacturing Kitting (Material Kitting / Internal Kitting)

Manufacturing kitting occurs before products reach a warehouse. As the name suggests, it is typically handled by the manufacturer at the manufacturing facility and not by the warehouse personnel of a wholesaler. It is further classified into two types:

- Material Kitting: It is similar to warehouse kitting, but happens at the manufacturer’s location. Kits are assembled there and shipped to wholesalers fully packaged, ready for storage and sale, facilitating the overall manufacturing process.

- Internal Kitting: It focuses on assembling the raw materials required for production into kits. This is specifically done to streamline the assembly of a final product. For instance, an employee in a furniture manufacturing business collects wooden panels, metal hinges, screws, brackets, handles, and manuals and places them together in a bin specific to a wardrobe model. This kit is transferred to the assembly workers, who build the final furniture piece.

Private Label Kitting

Here, the business outsources kitting to a third-party provider. These providers assemble and ship kits under the business’ brand name, often including branded marketing materials, thereby reducing the manual labor involved in the assembly process. This method is useful for businesses that don’t manage their own manufacturing or warehouse operations, but at the same time want to offer curated product experiences.

For instance, imagine you are a healthcare brand that wants to sell a product called “30-Day Immunity Support Kit”. It includes a Vitamin C supplement, a Zinc tablet, and a herbal immune support capsule. Now, instead of manufacturing the supplements yourself, you source each item from certified manufacturers that allow private labeling.

You then hire a third-party fulfillment company that combines the products into a single branded kit. They apply your custom labels and package everything in a branded box. Finally, they ship it directly to your customers on your behalf.

On-Demand Kitting

In this, customers can personalize what goes into their kit. The individual items are stored separately in the warehouse and are added to a kit only when the order is received. Each item in the kit may have its own SKU, and the final kit is packaged just in time for shipping. This approach is ideal for businesses offering personalized or ‘build-your-own product’ experiences such as meal boxes, beauty kits, or wellness bundles.

What are Some Examples of Kitting?

Here are some examples of kitting from different industries:

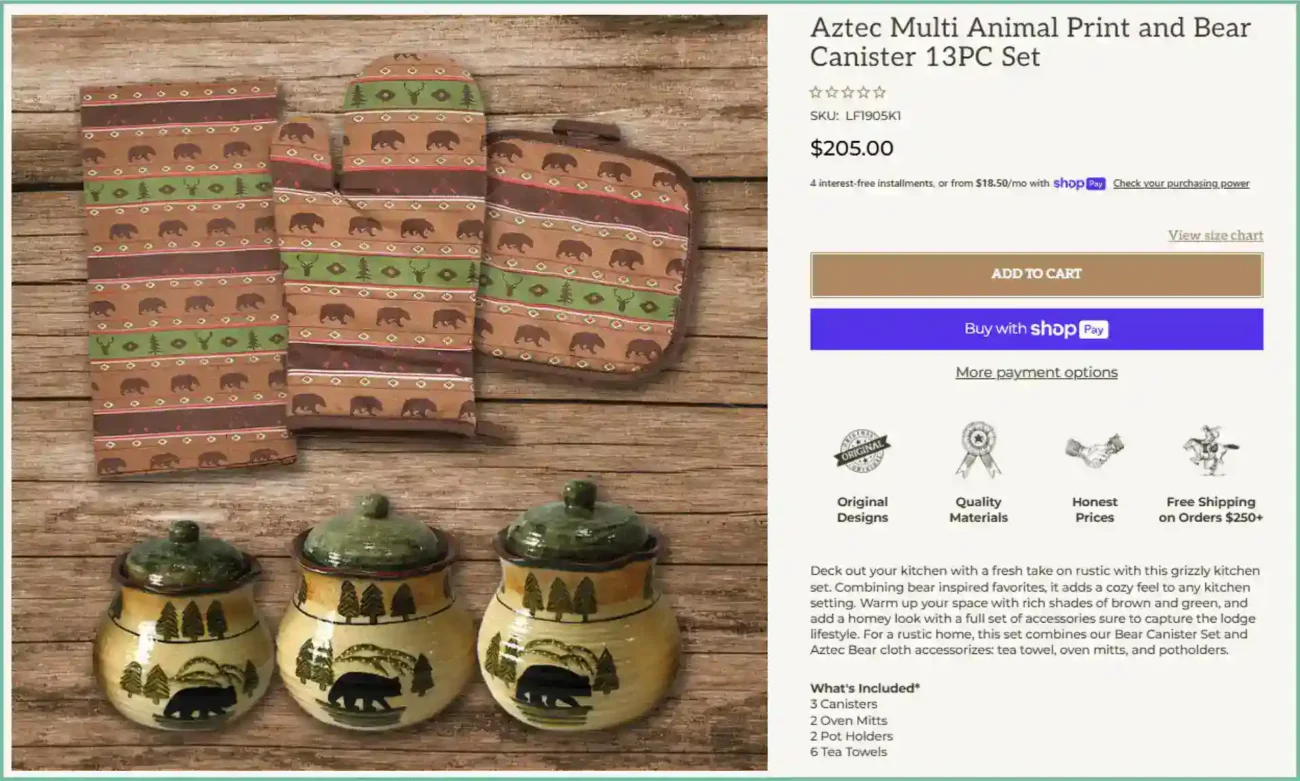

1. Paseo Road sells pre-defined kits covering home decor and kitchen accessories. For instance, their Aztec Multi‑Animal Print & Rustic Bear set combines multiple coordinated kitchen accessories into one cohesive SKU, delivering an antique aesthetic.

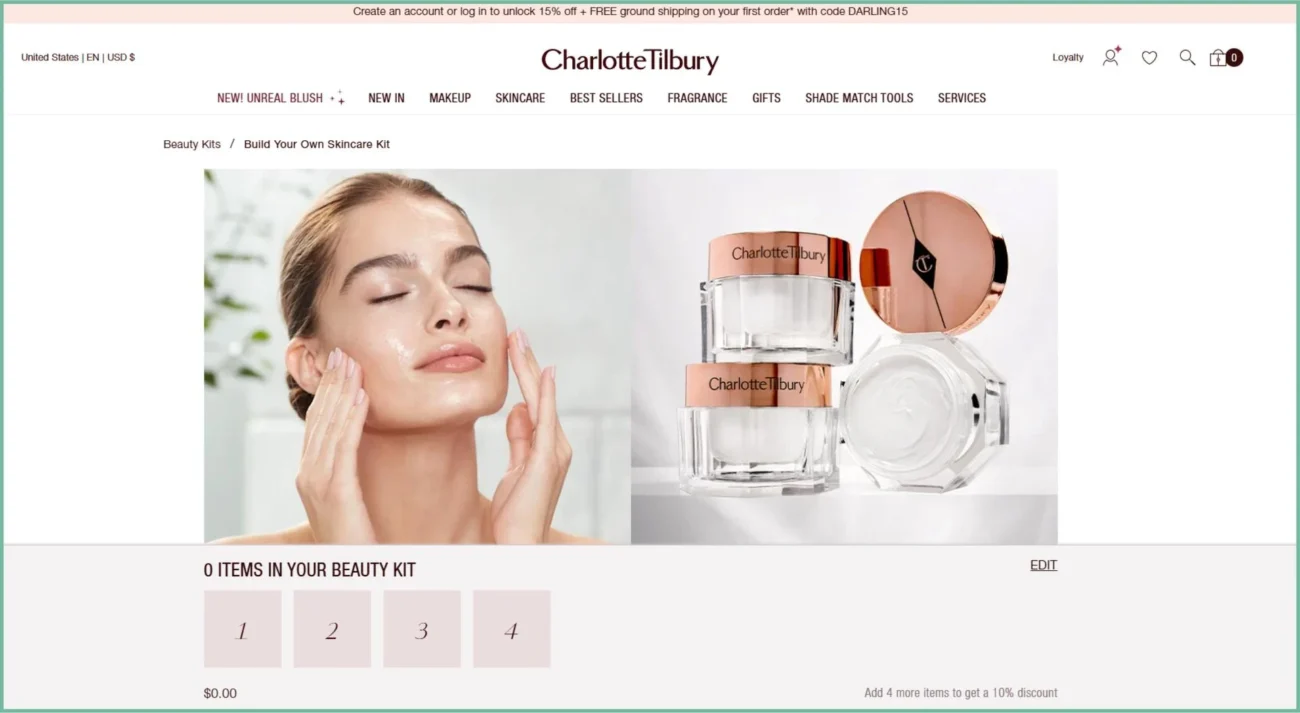

2. Charlotte Tilbury’s Build Your Own Skincare Kit lets buyers assemble a custom skincare set. They can choose their own products, which are then packaged in a branded gift box. This is a classic example of on-demand kitting.

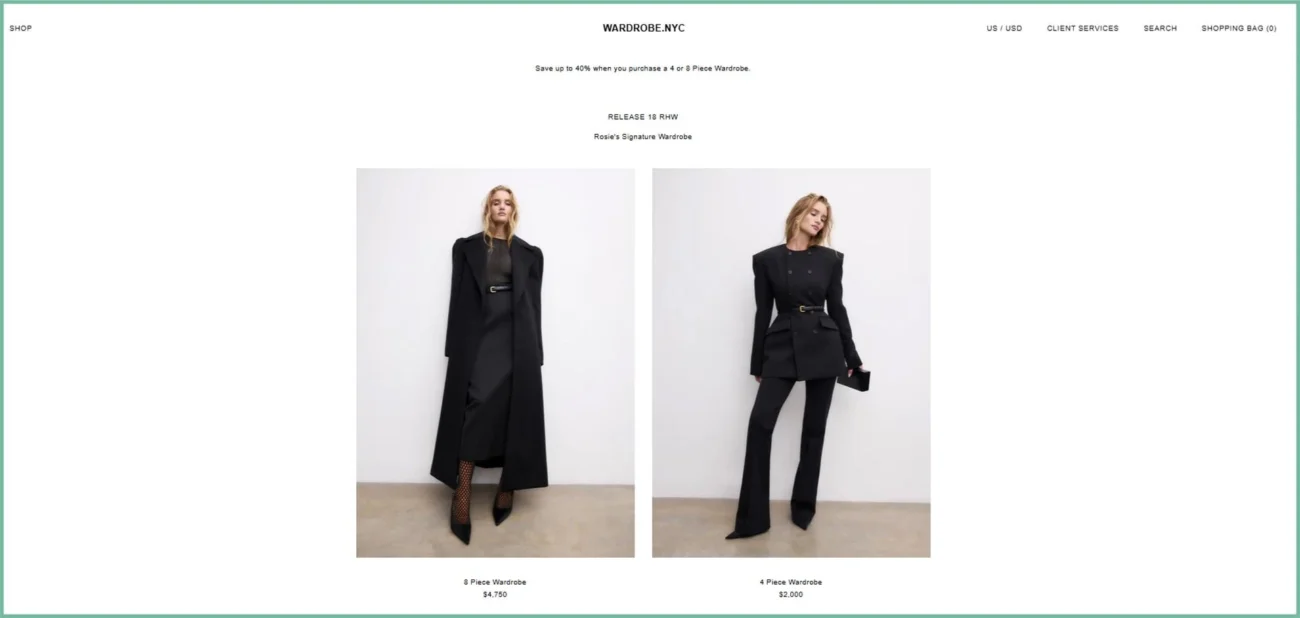

3. Wardrobe NYC, the minimalistic fashion brand, offers curated “wardrobe” kits, either 4-piece or 8-piece sets, sold as single SKUs at an attractive price. It often features signature minimal essentials like blazers, tops, and leggings.

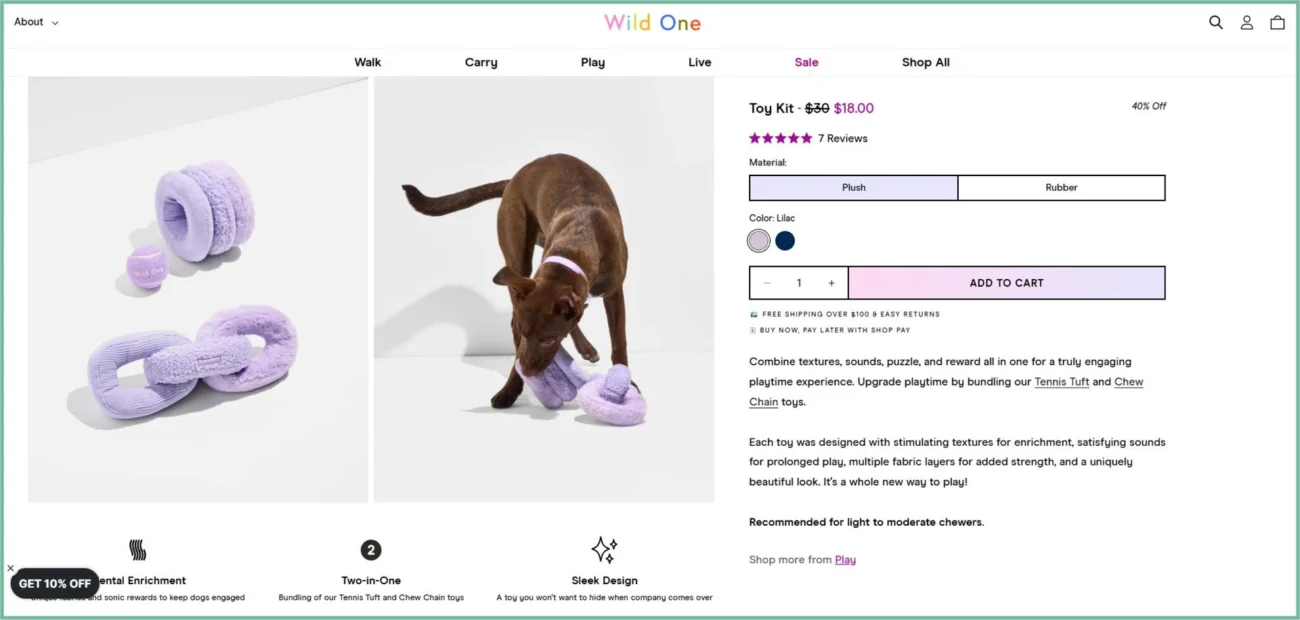

4. Wild One is known for offering kits involving pet essentials. It combines toys, walking gear, and wellness items for pets into thoughtfully curated kits. Their Plush Toy Kit, for example, brings together durable, play-ready toys in a single, value-packed SKU.

What are the Benefits of Kitting?

Kitting is more than just grouping products. When used right, it can be a smart operational strategy that can offer measurable benefits across your supply chain. Here are some of its benefits:

- Fewer errors: With pre-grouped items, your warehouse staff don’t need to locate each item of an order individually. This automatically reduces the likelihood of missing or incorrect items being shipped. Ultimately, you will experience fewer customer complaints, returns, and refunds.

- Efficient use of warehouse storage space: Kitting is a great way to consolidate storage to a great extent. You are no longer wasting valuable shelf space for storing individual SKUs. Instead, you are organizing inventory in bulk units. This not only frees up room for other inventory but also improves warehouse layout and picking routes.

- Lower labor costs: Kits reduce the number of touches required to complete an order. In other words, employees spend less time picking items for an order. This leads to faster order processing, less repetitive work, and the ability to ship more orders with less effort. Over time, this means you can scale without significantly increasing headcount, reducing your overall labor costs.

- Lower shipping costs: Kits are often packed more efficiently. This results in smaller, more compact packages, which, in turn, lead to reduced dimensional weight (DIM) charges. It will also eliminate the need for multiple boxes per order. Finally, having predefined kits, with the contents of each kit already determined, makes it easier to plan packaging, such as the ability to use standardized box sizes. All of this contributes to cost savings, reduced shipping expenses, and fewer logistics surprises.

- Higher sales revenue: Kitting can increase your Average Order Value (AOV) by encouraging customers to buy more at once. Well-designed kits not only provide convenience to your customers but also give the impression of value, which encourages them to complete the purchase. They’re also great tools for clearing your inventory. You can easily include low-selling complementary products as part of a kit. All of this gives an instant boost to your sales revenue.

- Faster shipping: Fewer SKUs to pick means faster picking. Pre-kitted items mean less decision-making at the time of packaging. This leads to quicker turnarounds, which is especially important for businesses offering same-day or next-day delivery. Faster shipping also results in happier customers and can become a competitive differentiator.

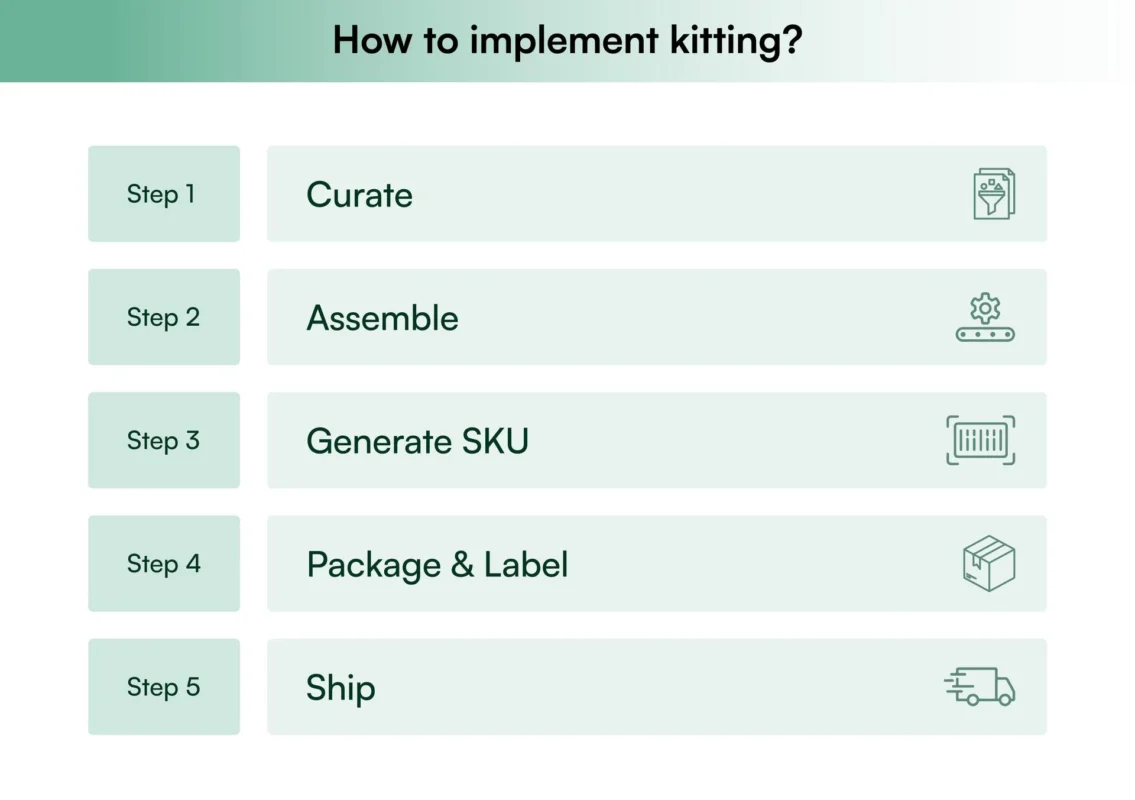

How to Implement Kitting?

Here’s a step-by-step breakdown of how to successfully implement kitting in a manufacturing or wholesale environment:

Step 1: Curate the kit

Start by identifying which products should be grouped together. This could be based on common ordering patterns, complementary product usage, customer-specific requirements, and orders with special promotions. The goal is simple: the curated kit should offer operational or commercial value, like simplifying procurement for the buyer or streamlining fulfilment for your business.

Step 2: Assemble the kit

Once the kit components are finalized, assign responsibility for collecting and assembling them. This step takes place on the production floor or the warehouse space, usually in a dedicated kitting area. It could even take place at the supplier’s location, in case of material kitting. While assembling the kit, components should be counted and inspected. Finally, they should be grouped together in advance to minimize packaging errors later in the workflow.

Step 3: Generate an SKU for the kit

To treat the kit as a single product within your inventory and order management systems, you need to create a unique stock keeping unit (SKU). This simplifies everything from inventory management to order tracking and reporting to the reordering process. It also helps your sales and customer service teams refer to the kit as one standardized product rather than multiple individual ones.

Step 4: Package and label kits

Package the assembled kits using materials that are suitable for both protection and efficient handling during shipping. Clear and consistent labeling is also critical for ensuring the kits are received and stocked correctly by the buyers.

Step 5: Ship the kits

Once labeled, the kits are ready for shipping. Whether shipping to a warehouse, distributor, or directly to a retailer, ensure your logistics team is trained to handle kits as single units. This helps maintain a smooth and accurate delivery process.

What are Some Best Practices to Follow in Kitting?

Here are the best practices to help you get the most out of your kitting strategy:

1. Draft a plan much before you start the kitting process

This includes the basic steps of deciding which products to kit, defining the end goal (e.g., faster shipping, customer convenience, clearing inventory, etc.), and identifying the required resources, such as packaging materials, staff, space, and technology. A well-thought-out kitting plan helps align teams, avoid last-minute confusion, and ensures smooth execution from the very first order.

2. Use the right packaging material

Kits are often shipped as single units, so packaging plays a critical role in protecting the items and presenting them professionally. Use materials that are both durable and space-efficient; for instance, foam inserts, bubble wrap, and corrugated dividers to reduce the risk of damage. The right material can also minimize shipping costs and enhance the unboxing experience for the end user.

3. Create clear, accurate documentation

This includes assembly instructions (for internal teams), contents list (for inventory and recipients), and proper labeling. Documentation helps avoid mistakes during assembly and shipping, and is especially important in regulated industries like pharmaceuticals, electronics, or industrial manufacturing. Including manuals, MSDS sheets, or compliance labels when necessary ensures your kits meet quality and safety standards.

4. Pay attention to inventory management

Kitting affects how inventory is tracked and managed. If not monitored correctly, it can lead to stockouts of individual components or overstocking of slow-moving kits. To prevent this, integrate your kitting process with your inventory management software system. This ensures real-time visibility of both standalone items and kits, so your purchasing, sales, and warehouse teams stay aligned. Accurate inventory tracking is key to avoiding disruptions and maintaining fulfillment speed.

Next Step: Empower your Kitting Strategy with the Right Tool

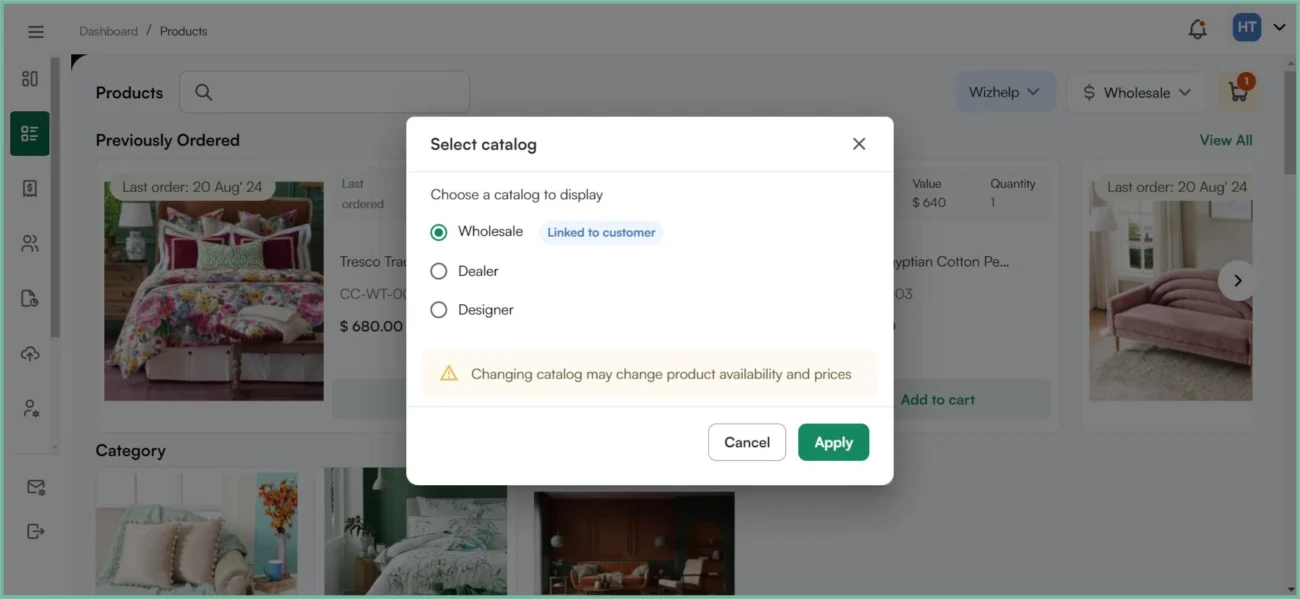

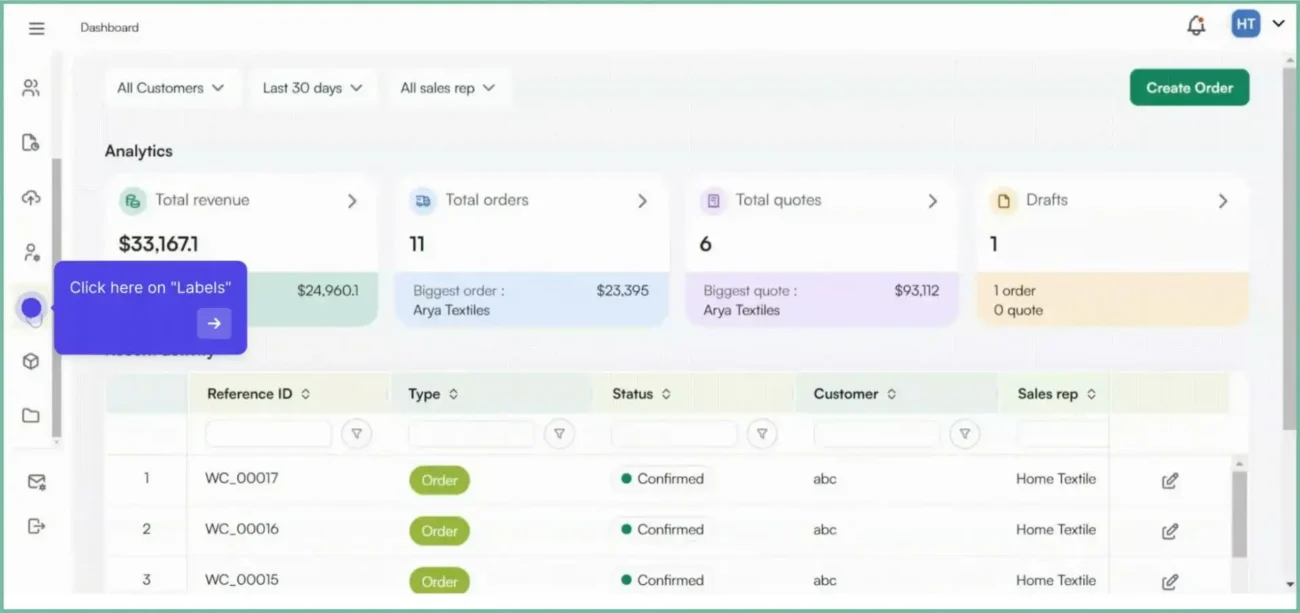

WizCommerce, a B2B commerce solution, has been designed with a singular goal: to streamline complex B2B buying journeys, enabling manufacturers, distributors, and wholesalers to sell faster and manage orders more efficiently. As part of this mission, WizCommerce allows you to build and manage kits with great ease. You can create a single, sellable unit of multiple products, giving buyers a seamless way to order a kit. Here’s how WizCommerce makes it easier to create, manage, and sell product kits efficiently:

- ERP integration: WizCommerce integrates with leading ERP systems to ensure that your kits are synced in real time

- Customer-specific pricing & volume-based discounts: With support for tiered pricing and customer-specific rate cards, you can easily apply negotiated pricing or offer volume discounts on kits.

- Analytics: WizCommerce’s intelligent AI recommendation engine analyzes historical order data to suggest frequently bought-together products for you to create high-converting kits.

- Generate labels: The platform not only offers default label templates to choose from but also allows you to create customized labels so that you can create one to meet the specific needs of your kit and deploy it directly on the platform.

Summing up

Kitting can be your key to simplifying complex order fulfillment and boosting customer satisfaction in one go. Whether you’re bundling components for efficient manufacturing or creating curated product kits for retailers, having a clear and efficient kitting process is essential for operational success. With the right technology, like WizCommerce, you can take the complexity out of kitting. WizCommerce equips your business with all the necessary features to manage kits at scale. Book a demo with WizCommerce today to see it in action.

Frequently asked questions

What do you mean by kitting?

Kitting refers to the practice of grouping individual, related items into a single item “kit” or package that can be picked, packed, and shipped as one unit. Instead of handling each component separately, kitting streamlines order fulfillment by assembling all necessary parts in advance, saving time and reducing errors.

Is it kitting or kiting?

The correct term is “kitting”. It refers to the practice of grouping individual, related items into a single “kit” or package that can be picked, packed, and shipped as one unit.

What is kitting in a warehouse?

In a warehouse, kitting is the operation where warehouse staff or automated systems gather multiple products with unique stock keeping units (SKUs) and combine them into a single inventory item or kit. These kits are then stored, tracked, and issued as one product, simplifying inventory management and speeding up the packing process for orders containing multiple components.

What is the process of kitting?

The kitting process typically starts with identifying which components belong together (based on orders or product bundles), retrieving those SKUs from inventory, and assembling them at a designated packing station. Once items are grouped, the kit is labeled with a unique kit-level barcode, quality-checked, and returned to storage or sent directly to shipping. Kanban or pull-based systems may trigger re-kitting when kit stock falls below set levels.

What is an example of kitting?

An example of kitting is a subscription box service that sends monthly beauty samples: technicians pick a lipstick, mascara, facial mask, and brochure, place them together in a branded box, seal it, and label it as one bundled SKU. This way, when a subscriber orders the box, the warehouse simply grabs and ships the pre-assembled kit rather than picking each item individually.